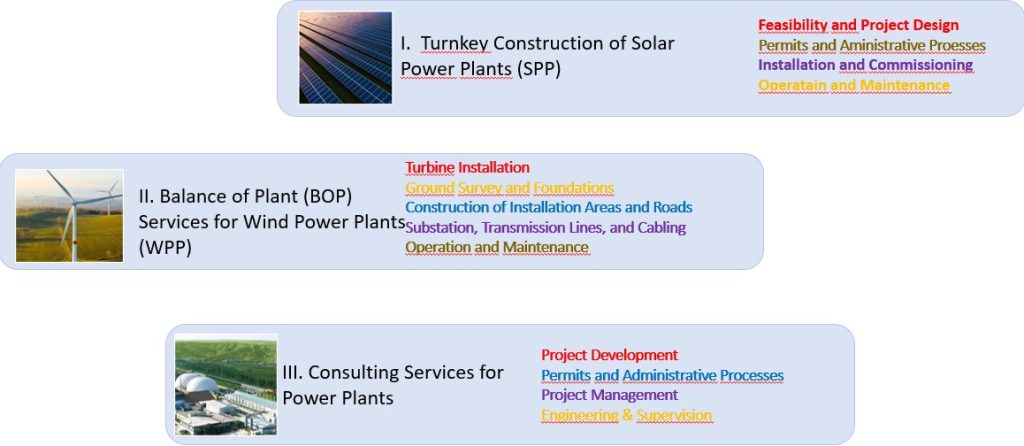

Our Activities

WPP OPERATION & MAINTENANCE SERVICES

- Formation of a team in accordance with the turbine model and operating conditions.

- Analysis of condition monitoring system data, inspection of identified irregularities, and organized planning of solutions with relevant departments.

- Performing tests and analyses through predictive maintenance, early detection of potential irregularities, and planned resolution.

- Resolution of occurring failures and/or ensuring solution coordination with relevant departments.

- Recording failures and irregularities and conducting root cause analysis.

- Implementation of improvement applicaitons.

WIND TURBINE MECHANICAL INSTALLATION AND ELECTRICAL WORKS

According to the turbine model;

- Transportation Services

- Crane Services

- Mechanical Assembly

- Electrical Assembly

Turnkey or partial provision of the above services

PREVENTIVE MAINTENANCE SERVICE

Formation of maintenance teams qualified according to turbine models and operating conditions, periodic and preventive maintenance of main systems such as;

- Foundation and Towers

- Converter System

- Pitch System

- Power Cabinet

- Grounding and Lightning Protection Systems

- Generator

- Hydraulic System

- Brake Systems

- Yaw System

- Blades

- Drive Train

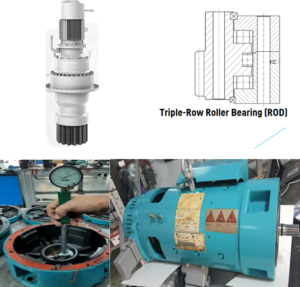

UP-TOWER REPAIR SERVICES

- Pitch Gear replacement

- Yaw Gear replacement

- Elastomer Replacement

- HSS bearing replacement

- Generator bearings replacement

MAJOR OPERATION SERVICES

- Main bearing & Shaft exchange

- Blade bearing exchange

- Main Gear Box exchange

- Generator exchange

ENGINEERING SOLUTIONS

Design and manufacturing of equipment in compliance with standards for specific turbine models;

- Lifting tools

- Installation & De-installation Tools

- Rotor Stand

- Blade fixtures

SUPPLY & REPAIR CHAIN

Provision of safe supply and sustainable repair processes for essential equipment compatible with turbine models:

- Blade bearing

- Main bearing

- Pitch motor

- Pitch gear

- Yaw motor & gear

- Main gear box

- Generator

- Brake Systems